The joining of the wires at the intersection is achieved by electric resistance welding. This is by a combination of heavy electric current (applied at low voltage) passed through the junction of wires, combined with heavy mechanical pressure. A solid state thyristor regulated electronic control ensures very fine control of time (in cycles) and current amplitude (total phase angle).

All the spacings between wires are controlled by an automatic mechanism of high reliability materials. The wires used in the fabric are cold drawn from controlled quality mild steel wire rods with carbon contents generally less than 0.15%. WWF is manufactured conforming to IS:1566/1982 with long and cross wire spacing varying from 25mm to 400mm. The wires conform to IS:432-Pt II/1982 which specifies an ultimate tensile strength of 570 N/mm2 and a characteristic strength of 480 N/mm2. Wires used for manufacture of fabric are generally in the range of 2mm to 12mm diameter.

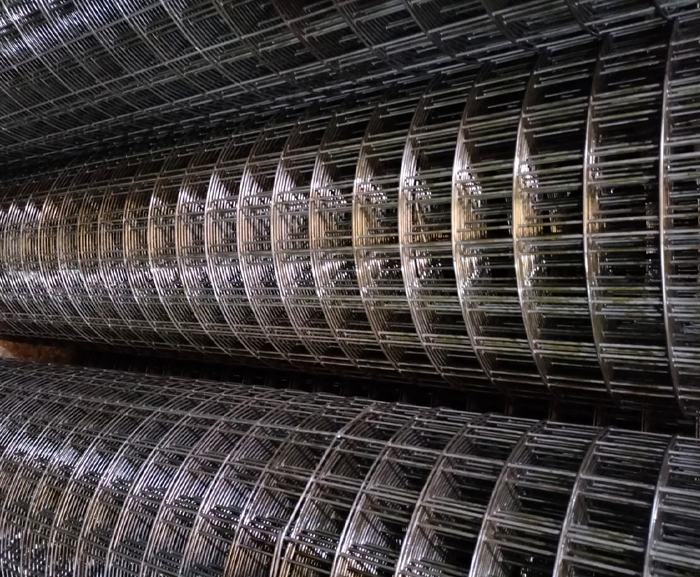

We have two manufacturing units which are equipped with state-of-the-art machinery producing G.I. and M.S. Welded Wire Mesh, Square and Oblong Mesh, Chain-Link Fence, Gabions, and one unit for drawing M.S. & Binding Wire.